When installing, the first step is to check the safety and quality of the grinding wheel. The method is to gently tap the side of the grinding wheel with a nylon hammer (or a pen), and the sound is clear and crisp, so there is no problem

The positioning problem is where the grinder is installed, which is the first issue we need to consider during the installation process. Only after selecting a reasonable and suitable location can we proceed with other work. Grinding machines are prohibited from being installed in areas directly facing nearby equipment and operators, or where people often pass by.

Generally, larger workshops should have dedicated grinding machine rooms. If a dedicated grinding machine room cannot be set up due to the terrain limitations of the factory building, a protective baffle with a height of no less than 1.8m should be installed on the front of the grinding machine, and the baffle should be firm and effective.

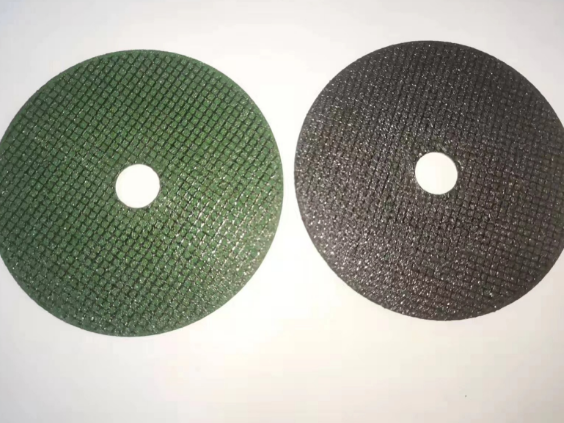

The imbalance of the grinding wheel is mainly caused by inaccurate manufacturing and installation of the grinding wheel, which causes the center of gravity of the grinding wheel to not coincide with the rotation axis. The harm caused by imbalance is mainly manifested in two aspects.

On the one hand, when the grinding wheel rotates at high speed, it causes vibration, which can easily cause polygonal vibration marks on the surface of the workpiece; On the other hand, imbalance accelerates the vibration of the spindle and the wear of the bearings, which can lead to the rupture of the grinding wheel and even accidents in severe cases. Therefore, it is required that the sand office building with a straight diameter greater than or equal to 200mm should first undergo static balance after installing a chuck. When the grinding wheel is reshaped or found to be unbalanced during work, the static balance should be repeated.

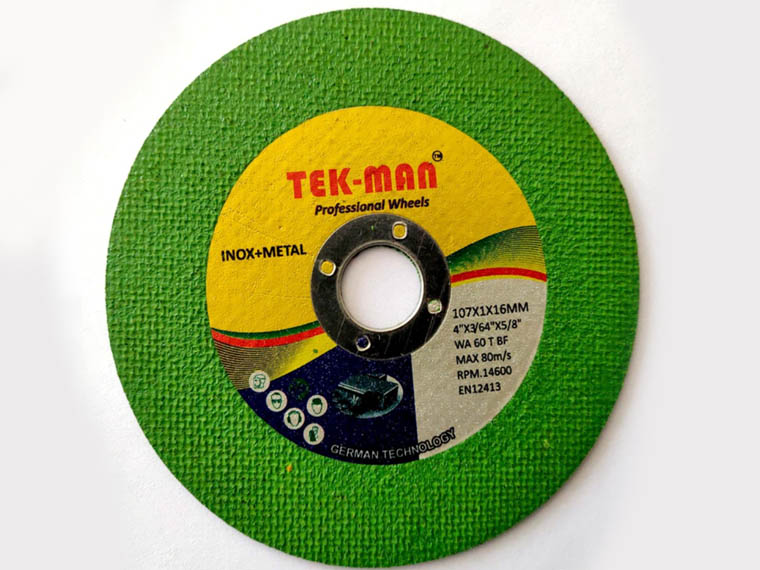

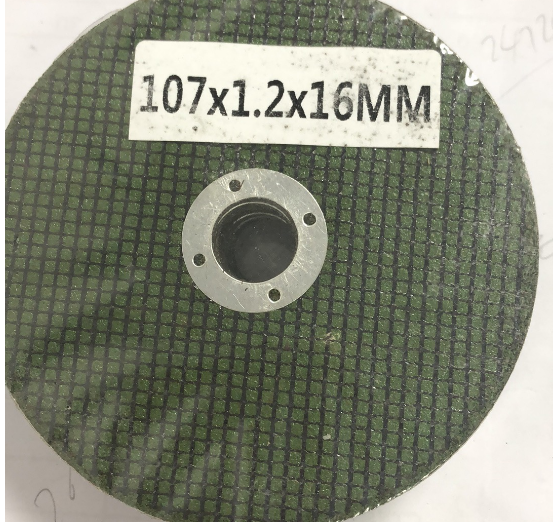

The matching problem mainly refers to the installation and matching of the chuck and grinding wheel. According to the standard requirements, the diameter of the grinding wheel chuck shall not be less than 1/3 of the diameter of the installed grinding wheel, and corresponding regulations stipulate that when the grinding wheel is worn to a diameter 10mm larger than the chuck diameter, a new grinding wheel should be replaced. There is a matching problem between the chuck and the grinding wheel, otherwise such a situation will occur, causing waste of equipment and materials due to the "big horse pulling the small car"; 'A small horse pulling a big cart' does not meet safety requirements and can easily cause personal accidents. Therefore, a reasonable match between the chuck and the grinding wheel can save equipment and materials on the one hand; On the other hand, it meets the requirements for safe operation. In addition, a cushion with a diameter greater than 2mm and a thickness of 1mm~2mm should be installed between the grinding wheel and the chuck.

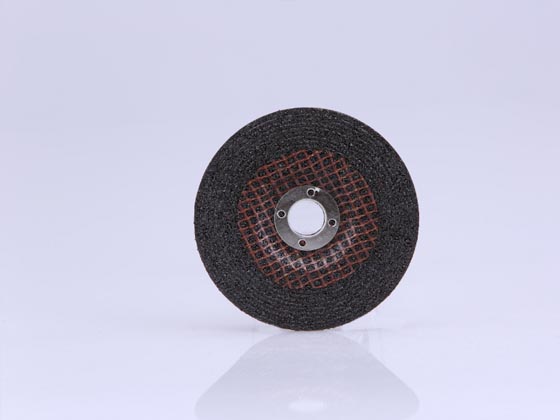

The protective cover is the main protective device of the grinding machine. Its function is to effectively cover the debris of the grinding wheel when it is damaged due to reasons during operation, ensuring the safety of personnel.

The shape of the grinding wheel protective cover can be circular or square, and its opening angle is not allowed to exceed 90 °; The material of the protective cover is steel with a tensile strength not less than 415N/mm2. When replacing a new grinding wheel, the installation of the protective cover should be firm and reliable, and the protective cover should not be dismantled or discarded arbitrarily.

The silent screen board is one of the main protective accessories of the grinding machine, This device must be installed when the opening of the protective cover is greater than or equal to 30 degrees above the horizontal plane of the spindle. Its main function is to block the flying noise during the grinding process to avoid injuring the operator. It is installed at the positive end of the protective cover opening, and the width should be greater than the width of the grinding wheel protective cover, and it should be firmly fixed on the protective cover. In addition, the gap between the circular surface of the grinding wheel and the baffle should be less than 6mm.

The bracket is one of the commonly used accessories for grinding machines, with a specified grinding wheel diameter of over 150mm